TechnologyOur technology

Multi-element Co-precipitation Technology

In conventional manufacturing methods, multiple elements may appear to be uniformly mixed at first glance, but they may be unevenly distributed at the atomic level. Multi-element co-precipitation technology is a technique to uniformly disperse and precipitate multiple elements inside particles, utilizing a method known as co-precipitation.

| Overview | For example, when manufacturing nickel-based materials as precursors for lithium-ion batteries, doping aluminum to the nickel increases thermal stability and improves safety. In this process, we not only simply mix multiple elements such as nickel and aluminum, but also co-precipitate them (a method of precipitating multiple elements simultaneously to create a homogeneous precipitation while maintaining proportionality) to produce products in which the elements are uniformly dispersed, down to the atomic level, inside the particles. In order to achieve uniform dispersion and co-precipitation of multiple elements, it is necessary to optimally control reactions according to the species and ratios of the elements to be mixed. Based on our knowledge and expertise, we have the technology to co-precipitate multiple elements under appropriately controlled conditions. |

|---|---|

| Advantages | Eliminates variations in quality for each particle, contributing to more stable battery performance |

| Utilized in | Lithium-ion (Li-ion) battery Nickel-metal hydride (Ni-MH) battery |

Ni

Co

Mn

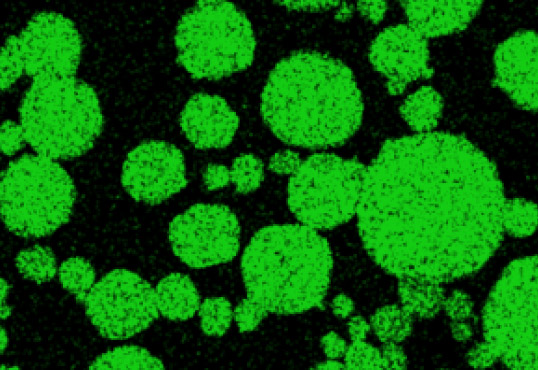

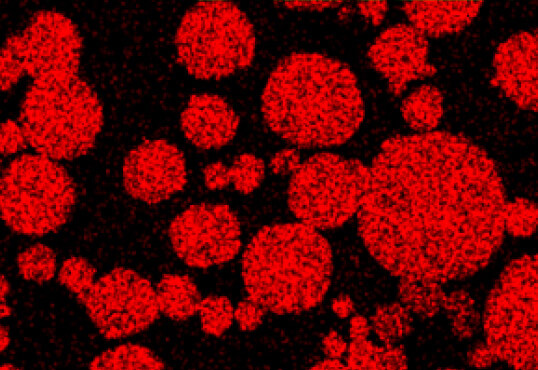

Measurement of the elemental distribution of products manufactured using co-precipitation shows that each contained element is uniformly distributed within a single particle, and, additionally, each particle in the particle group has a similar elemental distribution. This means that each element is precipitated simultaneously when hydroxide particles are precipitated in the neutralization process. We have been able to achieve this elemental distribution state by controlling the reaction conditions because of our expertise.

Co-precipitation of Multiple Elements

The "multi-element co-precipitation technology" that enables co-precipitation of multiple elements is one of our core technologies, but the selection (by classification and ratio) of multiple elements to be co-precipitated, is also a key aspect of highlighting cathode material manufacturers’ skills.

| Elements to be co-precipitated | Effect |

|---|---|

| Nickel | Increase battery capacity |

| Cobalt | Stabilize performance |

| Manganese | Cost reduction |

| Aluminum | Thermal stability Improved cycle performance |

| Elements to be co-precipitated | Effect |

|---|---|

| Nickel | Increase battery capacity |

| Cobalt | Improved high temperature characteristics |

| Zinc | Improved cycle performance |

Rechargeable batteries can be used over and over by recharging, but their capacity gradually decreases as they are repeatedly charged and discharged. This is called the cycle service life, and the degree of deterioration of capacity that occurs with numerous charge-discharge cycles is defined as the cycle performance. In other words, as you can see on the tables above, co-precipitated "aluminum" and "zinc" have the effect of increasing the service life of batteries.

Tanaka Chemical Corporation takes into account the characteristics of each element as described above, deriving the optimal combination and proportion of elements that can meet our customers' requirements, and co-precipitating them into high-performance materials.